Leading Functions to Try To Find in an Industrial Coffee Grinder

When assessing an industrial coffee grinder, it is important to determine crucial features that affect both performance and long life. Consistency in grind size is important for ideal removal, while adjustable grinding rate permits for an equilibrium in between effectiveness and high quality. In addition, the option of materials and design adds substantially to sturdiness and ease of maintenance. However, the subtleties of these attributes can significantly influence not only the top quality of coffee generated but also the general functional performance. Understanding these elements is important for making an informed decision that meets particular organization requirements.

Work Size Uniformity

While different aspects can affect the quality of made coffee, grind size uniformity stays extremely important in accomplishing ideal removal. The harmony of coffee grounds directly affects the brewing procedure, as unequal bit sizes can bring about over-extraction or under-extraction. This inconsistency results in imbalanced tastes, where particular notes may be overpowering while others are muted.

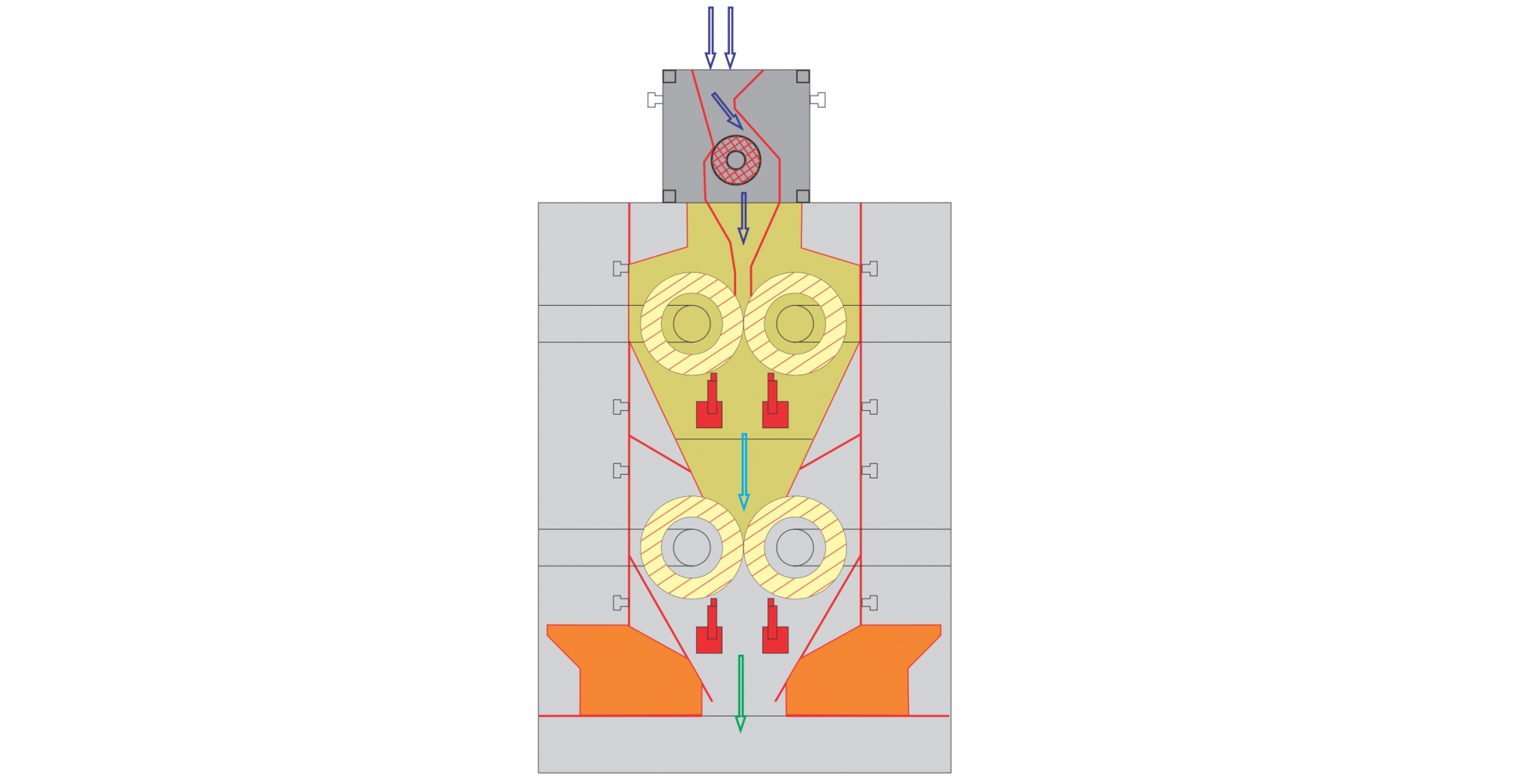

Industrial coffee grinders are developed to offer a high degree of accuracy, often utilizing burr grinding devices to make sure an uniform work size. Unlike blade mills, which can produce a mix of fine and crude fragments, burr grinders squash the beans between two surfaces, permitting much better control over work size. This uniformity is essential across various developing approaches, whether espresso, French press, or pour-over, as each method requires details work dimensions for ideal flavor extraction.

Furthermore, uniformity in work size contributes to the total performance of the brewing procedure. A consistent work permits also water flow, reducing the risk of carrying and improving removal performance. In recap, purchasing an industrial coffee mill with a concentrate on work size uniformity is essential for attaining premium coffee with preferable taste profiles.

Grinding Rate

Grinding rate plays a critical role in the overall efficiency of industrial coffee mills, straight influencing both the quality of the work and the performance of the operation. Industrial Coffee Grinder. Greater grinding speeds can dramatically improve the throughput, making it possible to refine bigger quantities of coffee beans in a shorter time frame. This is specifically vital for businesses that depend on high-volume production, such as coffee roasteries and cafes

Nevertheless, while rate is essential, it is similarly crucial to stabilize it with the quality of the work. Excessively high grinding speeds can produce warmth, which might negatively influence the taste account of the coffee by causing the beans to lose vital oils and scents. A mill that offers adjustable rate settings can supply ideal versatility, enabling drivers to customize the grinding process according to specific needs.

Furthermore, the grinding rate needs to be consistent to make certain uniformity in the grind dimension, further contributing to the overall taste and developing quality of the coffee. In summary, reviewing grinding rate is essential for picking a commercial coffee grinder that satisfies both efficiency and high quality demands.

Build Quality and Resilience

The effectiveness of a commercial coffee mill is not exclusively established by its grinding speed; construct top quality and durability are similarly important variables that influence lasting performance and dependability. A well-constructed mill will withstand the roughness of daily usage, making it a sound investment for Check Out Your URL any kind of industrial procedure.

Durability also prolongs to the grinder's electric motor and inner devices. Industrial coffee grinders need to be equipped with durable motors efficient in sustaining long term procedure without overheating. Additionally, recommended you read durable burrs are important, as they straight influence the quality of the grind and add to the total longevity of the device.

Simplicity of Usage and Upkeep

Consistently prioritizing ease of usage and maintenance can substantially boost the functional efficiency of an industrial coffee grinder. Straightforward features such as user-friendly controls and clear labeling are vital for minimizing downtime and making sure that operators can promptly adapt to the devices. An ergonomic design, consisting of height-adjustable hoppers and easily accessible grinding chambers, permits comfortable procedure and facilitates the loading and discharging of coffee beans.

Furthermore, convenience of upkeep is essential for prolonging the lifespan of the grinder. Equipment with detachable parts and elements created this website for fast cleansing can streamline maintenance tasks, lowering the time spent on regular maintenance - Industrial Coffee Grinder. Try to find mills that incorporate self-cleaning systems or need very little disassembly, as these attributes can conserve important labor hours

Furthermore, clear upkeep schedules and documents are important. Grinders that come with comprehensive user handbooks laying out upkeep treatments can aid operators stick to best practices, making certain constant performance and quality. By spending in a commercial coffee mill that highlights ease of usage and upkeep, organizations can enhance performance, lower functional expenses, and preserve the high standards expected in coffee manufacturing.

Noise Degree Reduction

When picking a commercial coffee grinder, sound degree decrease is a critical element that can substantially impact the work environment. High noise degrees can cause worker tiredness, decreased focus, and possible hearing damage gradually, making it necessary to choose a grinder developed with sound-dampening attributes.

Look for mills that include innovative noise-reduction innovations, such as sound-insulated housings and vibration-dampening mounts. These features help to minimize operational noises, creating a quieter environment for performance. Industrial Coffee Grinder. Furthermore, choosing grinders furnished with low-noise electric motors can better enhance audio decrease, making sure a more pleasurable workplace

Take into consideration the mill's general style. The positioning of the grinder within the workspace must be strategic.

Ultimately, purchasing a coffee grinder that prioritizes noise decrease not only enhances the convenience of staff members yet also aligns with a dedication to keeping a effective and secure workplace. This attention to detail can lead to improved staff member contentment and retention.

Conclusion

In summary, choosing an industrial coffee mill necessitates mindful consideration of numerous key features. Grind size uniformity is vital for ideal extraction, while flexible grinding speed assists in an equilibrium between throughput and quality.

Industrial coffee mills are developed to give a high level of accuracy, frequently using burr grinding systems to make certain an uniform work dimension. Unlike blade mills, which can produce a mix of fine and coarse bits, burr grinders crush the beans in between 2 surface areas, permitting for much better control over work dimension. In recap, investing in an industrial coffee grinder with a focus on work size consistency is essential for accomplishing premium coffee with desirable flavor profiles.

Grinding rate plays a critical function in the total efficiency of industrial coffee grinders, directly affecting both the quality of the work and the performance of the operation. A grinder that supplies adjustable rate settings can offer optimum flexibility, enabling drivers to customize the grinding process according to certain demands.